The Benefits of Partnering With a Cutting-edge Pipeline Manufacturer in 2023

In the ever-evolving landscape of pipeline infrastructure, lining up with an ingenious manufacturer in 2023 can considerably improve operational capabilities and reduce prices. By leveraging advanced technologies and tailored options, organizations can not only improve performance yet likewise ensure compliance with rigorous security requirements. Additionally, the longevity of products and smart tracking systems can result in considerable lasting financial savings. As sectors encounter raising regulative stress and sustainability obstacles, the concern emerges: exactly how can tactical partnerships truly drive makeover and promote an affordable side in such a dynamic atmosphere?

Access to Advanced Technologies

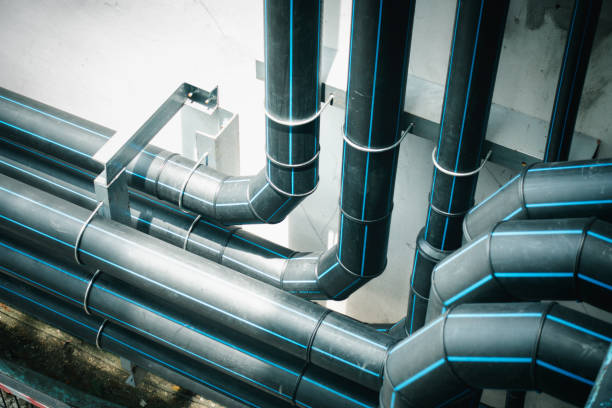

As markets evolve and the need for performance and sustainability rises, partnering with a pipeline manufacturer supplies access to sophisticated innovations that can considerably improve operational performance. These technologies include advanced materials, ingenious layout strategies, and innovative production processes that improve pipeline efficiency and toughness.

One substantial benefit of teaming up with a credible pipeline manufacturer is their financial investment in research study and growth. This commitment enables them to integrate the most recent innovations in pipeline innovation, such as wise sensing units and automation systems, which help with real-time tracking and upkeep. Such advancements not only improve security yet likewise reduce downtime, inevitably causing raised efficiency.

Additionally, makers frequently utilize innovative simulation and modeling tools to maximize pipeline style, guaranteeing that systems are tailored to certain environmental problems and operational demands. This degree of precision can cause extra effective transportation of liquids and decreased functional costs.

Custom-made Pipeline Solutions

Customized pipeline options provide customized design options that provide especially to the unique requirements of each project. This strategy not only enhances operational efficiency however additionally assures affordable remedies that align with financial restrictions. By partnering with a pipeline manufacturer, services can achieve peak performance and reliability in their pipeline systems.

Customized Style Options

In the domain of pipeline manufacturing, customized style choices offer substantial advantages that can boost operational performance and satisfy particular task demands (American Plastics LLC HDPE Pipeline Manufacturer). Customization allows makers to develop pipes that deal with the special demands of various sectors, ensuring peak performance across diverse applications

One of one of the most vital facets of customized layout options is the capability to choose products and configurations that line up with the specific environmental problems and functional stress of a job. This assures durability and long life, decreasing the danger of failures or pricey fixings. In addition, ingenious manufacturers employ sophisticated modern technologies such as 3D modeling and simulation, enabling specific design adjustments and improved quality control during the manufacturing process.

Tailored layouts likewise promote the assimilation of added attributes, such as specialized finishings or insulation, which can additionally enhance the pipelines' useful abilities. By working together closely with customers, producers can identify the specific needs and restraints of each project, leading to services that not just meet regulative criteria yet likewise exceed customer expectations.

Eventually, partnering with a maker that supplies customized style choices equips business to attain their task goals with confidence, ensuring that their pipeline systems are both effective and trustworthy.

Boosted Operational Effectiveness

Improved operational effectiveness is a vital benefit of partnering with a pipe manufacturer that provides tailored options. Tailoring pipeline layouts to meet particular operational demands allows companies to enhance their processes and enhance performance. Personalized pipelines can be crafted to fit unique stress, circulation prices, and environmental conditions, guaranteeing that the system operates at peak efficiency.

By using sophisticated materials and technologies, cutting-edge makers can produce pipes that lower friction losses and reduce maintenance requirements. This not only extends the lifespan of the infrastructure yet also leads to a much more constant and reliable circulation of materials. The assimilation of smart technologies, such as sensors and automated surveillance systems, additionally improves functional efficiency by offering real-time information on system performance.

Furthermore, personalized pipeline solutions promote better assimilation with existing facilities, allowing for smooth upgrades and developments as service requirements progress. This flexibility assists companies react rapidly to market demands without compromising performance. Overall, partnering with a supplier that specializes in customized pipeline options equips business to accomplish functional quality, enhance operations, and keep an one-upmanship in their sectors.

Cost-efficient Solutions

Partnering with a pipeline manufacturer that provides customized services not just boosts functional efficiency however likewise leads to significant cost savings. Custom-made pipeline options are developed to satisfy the details needs of a task, guaranteeing that sources are made use of efficiently and lowering unneeded expenditures. By resolving unique specifications, these solutions lessen product waste and optimize resource appropriation.

Furthermore, cutting-edge producers utilize progressed products and modern technologies, which can prolong the lifespan of pipes and minimize maintenance costs. Custom solutions can additionally enhance system compatibility, resulting in less disruptions and lower downtime. This not only supports an extra structured operations however also adds to total job cost decrease

Furthermore, a devoted partnership fosters cooperation, making it possible for producers to offer understandings and referrals based upon sector finest practices and emerging fads. This proactive strategy allows business to remain in advance of possible difficulties, further driving down prices connected with delays or redesigns.

Eventually, picking a pipeline manufacturer that prioritizes customized services not just yields prompt financial advantages but additionally settings companies for lasting success in a progressively affordable landscape. HDPE Pipe Supplier. By purchasing customized pipeline services, business can attain both functional excellence and significant expense performances

Enhanced Functional Efficiency

Considerable renovations in operational effectiveness can be attained through collaboration with a customized pipeline manufacturer. By leveraging advanced modern technologies and personalized designs, these makers enhance manufacturing procedures and improve system efficiency. This cooperation allows for the advancement of pipelines that are specifically tailored to satisfy the one-of-a-kind needs of numerous sectors, making sure ideal flow rates and minimal downtime.

Additionally, innovative pipeline manufacturers use modern products that not just boost resilience but likewise decrease maintenance demands. This causes fewer disruptions and an extra reputable pipeline system, ultimately raising overall functional performance. Furthermore, the assimilation of automated tracking systems enables real-time data analysis, promoting positive decision-making.

Such aggressive measures help in identifying possible problems before they intensify, enabling timely treatments that maintain procedures running efficiently. Training and support given by specialized producers also encourage internal groups to operate and keep these systems effectively.

Price Reduction Strategies

Collaborating with a specific pipeline manufacturer not just improves functional efficiency however additionally brings about effective expense decrease approaches. By leveraging advanced production methods and ingenious materials, these producers can give top notch pipelines that require less regular maintenance and substitute. This longevity converts directly into expense financial savings over the project's lifecycle.

On top of that, a specialized manufacturer usually supplies tailored remedies tailored to certain functional demands. This modification decreases waste and enhances resource utilization, further driving down costs. In addition, the assimilation of advanced modern technologies, such as automation and smart surveillance systems, boosts accuracy and minimizes labor expenditures connected with pipeline installation and surveillance.

Collaborations with ingenious pipeline suppliers can additionally result in economies of scale. By participating in bulk getting or long-lasting contracts, businesses can bargain far better rates and reduce total expense. Additionally, streamlining the supply chain with a dedicated manufacturer decreases delays and connected costs, making certain an extra effective project timeline.

Sustainability and Ecological Impact

The expanding focus on sustainability in the pipeline industry mirrors a wider dedication to environmental stewardship. As companies increasingly recognize their duty in mitigating climate adjustment, ingenious pipeline makers go to the leading edge of developing lasting services. By utilizing advanced products and modern technologies, they develop pipes that not just boost effectiveness yet additionally lessen ecological impact.

One significant element of sustainability is the emphasis on reducing greenhouse gas exhausts during manufacturing and procedure. Suppliers are adopting methods that focus on renewable resource resources, resulting in lower carbon footprints. The style of modern-day pipes commonly includes functions that assist in less complicated recycling and repurposing at the end of their lifecycle.

In addition, innovative makers are accepting water preservation methods in their procedures, guaranteeing that water usage is decreased and waste is efficiently handled. These efforts contribute to healthier ecological communities and show a commitment to liable source administration.

In partnering with a forward-thinking pipeline manufacturer, firms can improve their own sustainability initiatives, lining up with public expectations and regulatory requirements. This joint technique not just promotes a positive corporate image but also plays a vital role in building a lasting future for the sector.

Improved Safety And Security Requirements

Boosted Product Sturdiness

Improved product sturdiness is a vital consider enhancing safety criteria within pipeline procedures. The stability of pipeline systems relies heavily on the products utilized in their construction. Advanced materials, such as high-performance alloys and composite products, show exceptional resistance to tiredness, deterioration, and effect damage. This improved toughness decreases the risk of pipeline failures, leaks, and subsequent ecological hazards.

Ingenious pipeline makers focus on the choice of materials engineered to stand up to extreme conditions, including temperature changes and chemical direct exposure. By making use of these advanced materials, operators can considerably extend the lifespan of their pipeline systems, making sure trustworthy efficiency gradually. This durability not only reduces maintenance prices however also improves safety by reducing the regularity of maintenances that can subject employees to possible threats.

Boosted product sturdiness adds to governing compliance, as pipes need to fulfill rigorous safety and security standards. Suppliers that purchase developing durable materials assist drivers maintain conformity, thereby preventing pricey fines and project delays. To conclude, partnering with a supplier concentrated on enhanced material longevity straight associates to improved security standards, cultivating an extra secure operational setting for pipeline systems.

Advanced Safety Technologies

Many innovative safety innovations are changing the pipeline sector, dramatically boosting safety and security standards and functional effectiveness. As pipes come to be progressively essential for carrying crucial sources, the assimilation of ingenious modern technologies is required for making certain and minimizing risks compliance with strict policies.

One noteworthy innovation is the execution of real-time surveillance systems that make use of Net of Points (IoT) tools. These systems constantly track temperature level, stress, and flow rates, giving drivers with immediate insights to spot abnormalities that might show possible dangers (American Plastics LLC HDPE Pipeline Manufacturer). Automated shutoff valves are being deployed to without delay isolate sections of the pipeline in the occasion of a leak or rupture, substantially lowering ecological effect and safeguarding workers.

Additionally, progressed information analytics and machine discovering algorithms are being employed to anticipate maintenance demands, allowing for positive treatments before problems escalate. This anticipating method not only enhances safety yet also lessens downtime and functional expenses.

Teaming up with an ingenious pipeline manufacturer that prioritizes these advanced security innovations will certainly encourage firms to stay in advance of industry requirements, inevitably resulting in much safer and a lot more efficient operations. Accepting these innovations is important for fostering a culture of security and integrity in the pipeline industry.

Long-term Strategic Collaborations

These partnerships supply a system for constant improvement and adaptation to market demands. As modern technologies and laws evolve, a fully commited pipeline manufacturer can assist assure that your operations remain certified and competitive. This versatility is crucial in a rapidly changing market landscape.

Moreover, long-lasting partnerships foster count on and placement in objectives, which assists in much better communication and problem-solving. A common vision allows both parties to focus on sustainability and innovation, making certain that both firms can thrive together.

Additionally, such cooperations frequently cause advantageous pricing and boosted service terms, improving the general worth of he has a good point the collaboration. Ultimately, buying a lasting critical collaboration with an innovative pipeline manufacturer not only boosts operational capabilities but likewise placements your business for continual development and success in the pipeline sector.

Regularly Asked Concerns

How Do I Pick the Right Pipeline Manufacturer for My Demands?

To pick the appropriate pipeline manufacturer, examine their experience, product top quality, technological abilities, and compliance with industry standards. Additionally, take into consideration consumer assistance, customization options, and recommendations to assure placement with your details task demands.

What Industries Benefit Most From Innovative Pipeline Solutions?

Cutting-edge pipeline options significantly benefit sectors such as oil and gas, water monitoring, chemical handling, and renewable resource. These fields need advanced technology to enhance performance, safety, and ecological sustainability while resolving evolving functional difficulties.

Exist Financing Options Available for Pipeline Projects?

Yes, numerous financing options are readily available for pipeline jobs, including typical finances, government gives, public-private collaborations, and project financing. These choices can promote investment and sustain the growth of crucial framework in the market.

How Can I Examine a Supplier's Track record and Reliability?

To analyze a producer's track record and integrity, conduct complete research study by reviewing customer testimonies, sector accreditations, past job portfolios, and looking for recommendations. American Plastics LLC HDPE Pipe Solutions. Additionally, examine their economic security and adherence to safety and security and quality requirements

What Is the Normal Timeline for Pipeline Project Completion?

The normal timeline for pipeline task completion differs considerably based on task extent, governing approvals, and ecological evaluations, normally varying from numerous months to a couple of years, depending upon the complexity and location of the job.